The Industrial Technology program prepares students for high-demand jobs in the Central Valley, such as field service technician, industrial maintenance technician, maintenance mechanic, or maintenance repair mechanic.

Three-year average salary for full-time related employment: $49,329.

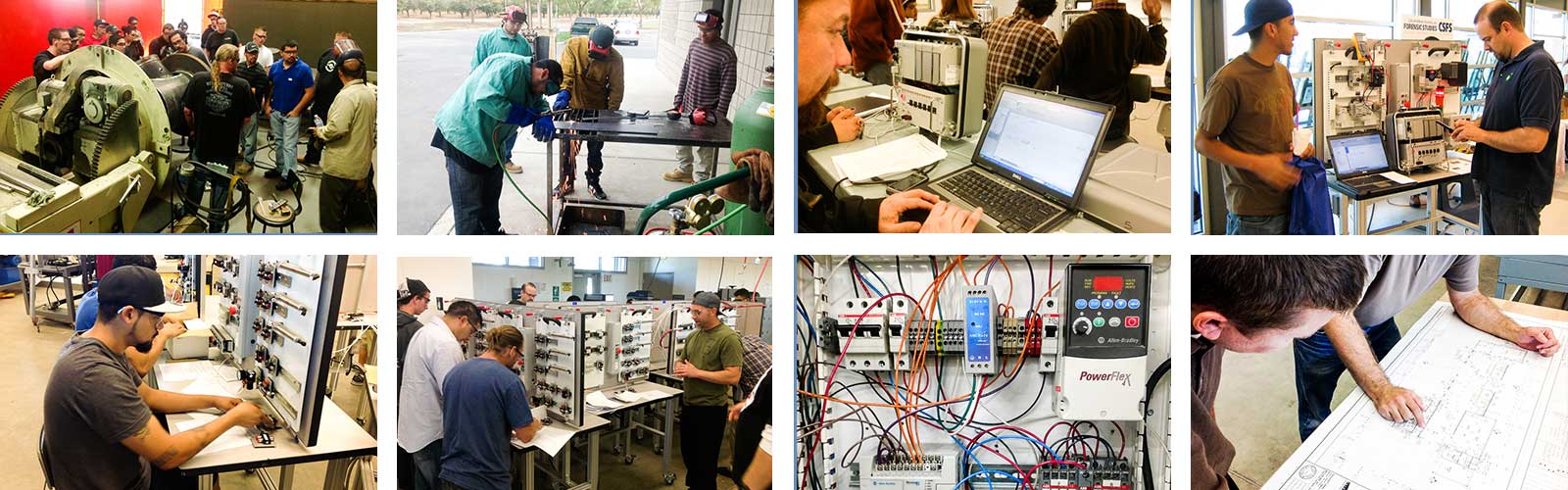

Gain hands-on, practical experience in welding, hydraulics, electricity, mechanical fundamentals, and machine alignment. Build skills in electronics, computerized equipment maintenance, and preventative/predictive maintenance. Learn and apply predictive and preventative maintenance methods; the basics of analysis, vibration analysis, and thermal analysis applications; and use and apply a computerized maintenance management system.

Earn a certificate or an Associate degree. The program begins in fall 2020.

Students can earn a certificate or associate degree. The program prepares students for the National Institute of Metal Working Skills (NIMS) Industrial Technician Maintenance (ITM) credentialing program.

The first step is to fill out the application!

This course covers interpreting machine operation and maintenance documentation; performing machine predictive preventative and maintenance procedures; reading and interpreting technical drawings; safely moving and storing materials and equipment; safely using hand tools for equipment maintenance and inspection, and practicing troubleshooting techniques. Upon successful completion, students will receive an OSHA 10-hour course completion card at the end of the training.

This course prepares students with the skills and knowledge to successfully adhere to mechanical power transmission safety rules. Students will learn to install, align, lubricate, and apply troubleshooting techniques to mechanical power transmission through chains, belts, bearings, and gear trains. The use of dimensional measuring tools will be applied to real-life applications.

This course teaches principles of hydraulic systems, including fluid power schematics, flow and pressure characteristics, filter and lubrication selection, hydraulic system components, and troubleshooting. Adherence to fluid power safety regulations will be emphasized.

This course covers how work, force, and energy are applied to principles of pneumatics using air compressors, air treatment, valves, logic devices, cylinders, and air motors. Adherence to fluid power safety regulations is emphasized.

This course introduces the theory of electricity and the relationship of voltage, current, resistance, and power in electrical circuits develops an understanding of AC and DC fundamentals, and applies formulas to analyze the operation of AC and DC circuits. This course also addresses the common symbols used in motor control circuits the fundamentals of electrical schematics and wiring diagrams the principles of relays, motor starters, switches, pilot devices, sensing devices, and indicator lights, and introduces the different types and operations of basic motor control circuits.